Ecological filters with a fan

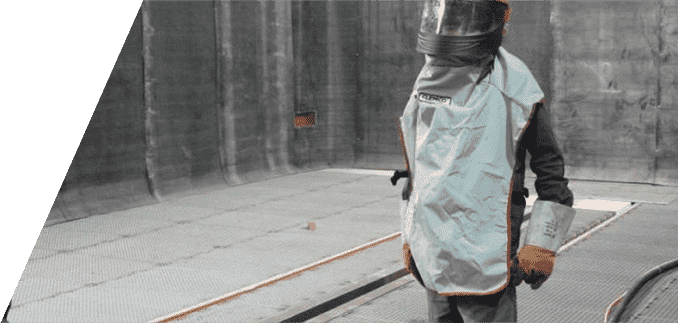

The OT JP filters are designed to remove dry mechanical impurities from air. The filter cartridge cleaning method (JET) allows for continuous operation without the need to shut down the fan during cleaning. The cartridge design of the filter has the advantage over other designs (sleeve, bag, etc.) in that it is relatively smaller with respect to these, thus occupies much less space with the same technical parameters. If the customer wishes, OT JP filters can be fitted with anti-static filter cartridges (e.g. for filtering air during metalization).

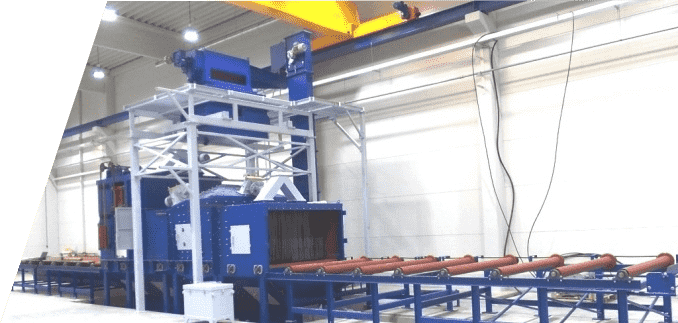

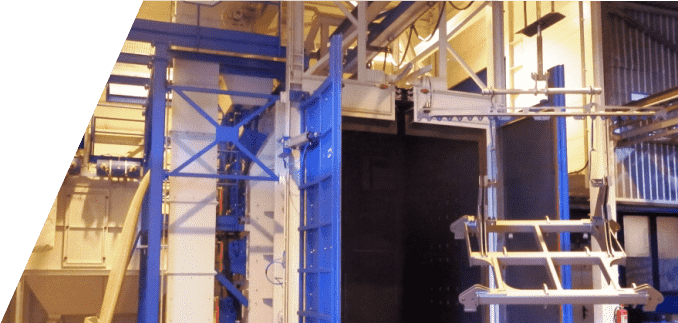

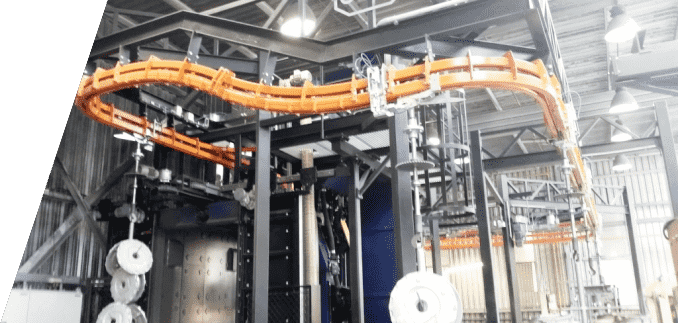

The fan can be placed on the "clean" side of the top of the filter, near the filter on the ground or on a pedestal. The outlet opening direction is chosen optimally according to the placement. The fan is usually connected to a filter using a steel sheet duct. The cross-section of the pipe is chosen so that the air velocity is within the range of 10 to 20 m / s.

The body of the filter is made of steel profiles and sheets. The lower part is funnel shaped and serves to collect removed impurities. This waste is automatically ejected through mechanical covers with counterweights into transparent plastic bags in which it is also disposed of. Filtering cartridges are located in the middle of the filter. They are fastened using bayonet closures from the "clean" side and their mounting or replacement does not require additional height. This is an advantage when deployed in low halls. The middle part of the filter further includes a separating chamber, which protects the filter cartridges against air shocks and serves for the separation of coarse dust. At the top of the filter are electromagnetic valves and air ducts with nozzles for blowing. For the perfect cleaning of the filter cartridges air pressure of about 5 - 5.5 bar is sufficient.

Filter operation is fully automatic and does not require operator interference.

Function description

A fully automatic cartridge JET filter. The cartridge cleaning is based on a counter-current principle. From the "clean" side, a short impulse of compressed air is fed into the filter cartridge to remove the collected dust from the cartridge surface. This dust falls into the collecting funnel and the valve release mechanism discharges it in the dust container without having to stop the fan. The time interval between the two blow cycles and the air pressure on the cartridge surface can be controlled continuously. In this way, it is possible to choose the optimal mode for cleaning the filter surface, thus achieving a long lifetime of the cartridges. This significantly reduces operating costs.

OTECO filters are produced with a filter area of 10 to 600 m2. The company guarantees the service life of the filter cartridges to be 8000 to 10000 hours of operation.