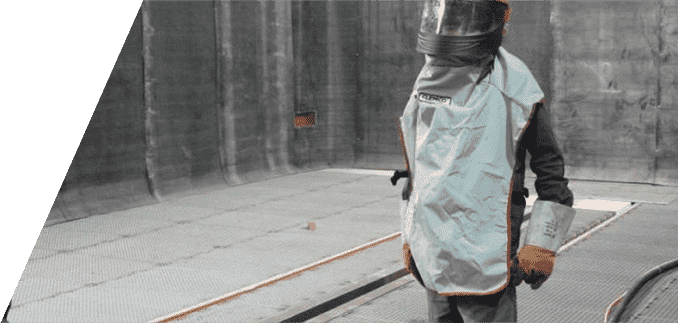

Manual injector cabins

The manual injector cabin is a pressurized air blasting machine for cleaning the surface of small to middle sized parts using the injector blasting unit. The worker inserts his hands into the blasting chamber through the oval openings on the front side of ther cabin. These openings are equipped with blast resistant rubberized gloves so dust and abrasive does not escape the chamber. The parts are inserted via a (folding or side) door or via pass-through side openings. The blasting process itself is started and stopped using a foot switch.

The standard equipment of the OTECO injector cabins includes:

- a stable steel cabin with (folding or side) doors

- complete protective lining of the working area with abrasion-resistant rubber curtains

- removable collecting funnel in the lower part of the machine for collecting the blasted abrasive and enabling quick replacement

- mechanical or motor driven rotary work table with a load capacity of 250 kg — optionally up to 1000 kg

- injector blasting unit including a blast head and a 10 mm diameter boron carbide nozzle

- blow gun for cleaning parts after blasting

- lighting

- side openings for pulling through long parts

- rollers to facilitate manipulation with long parts

In order for the injector cabin to work reliably, it must be connected to efficient suction. For this purpose, OTECO supplies an automatic environment-friendly filter with a fan alongside the cabin. It ensures continuous abrasive cleanness during blasting and prevents dust from escaping the chamber.

The company produces injector blasting cabins in three standard sizes.