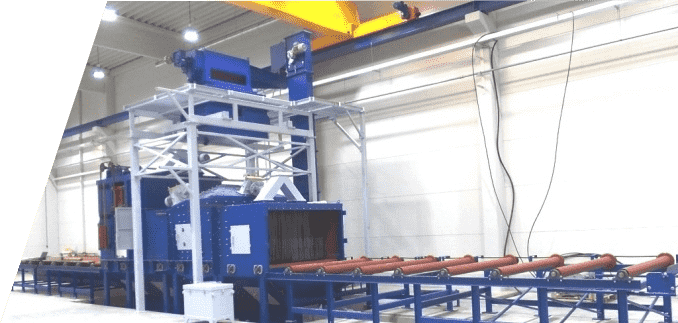

Manual pressure cabins

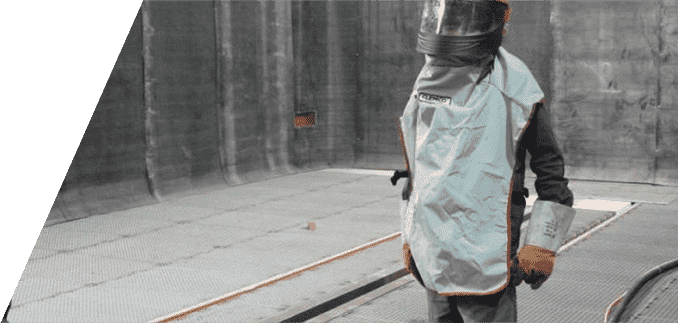

The manual pressure blasting cabin is a device designed for cleaning small to medium-sized parts. It is performed manually using a pressure blasting kit. It is possible to utilize any reusable abrasive. Another advantage of the pressure blast cabin over the injector cabin is the ability to achieve higher blasting capacity.

The blasting is performed manually using the holes for the hands on the front side of the machine. In order to eliminate escape of the abrasive and dust, the openings are equipped with gloves made of abrasion resistant rubberized material. The pieces are inserted in the cabin through the front two piece folding door or throught the side openings. The blasting process itself is started and stopped using a foot switch.

The standard equipment of the OTECO pressure cabins includes:

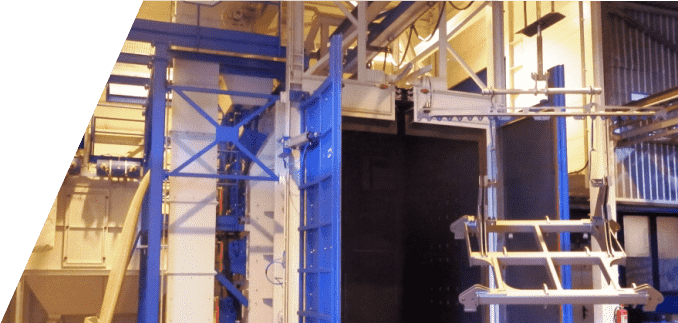

- a stable steel plate cabin with folding doors, equipped by a limit switch in accordance with safety regulations

- side openings equipped with rollers for easy manipulation of pass-through parts

- complete protective lining of the working area with removable abrasion resistant rubber curtains

- mechanical or motor driven rotary work table with a load capacity of 250 kg — optionally up to 1000 kg

- blow gun for cleaning parts after blasting

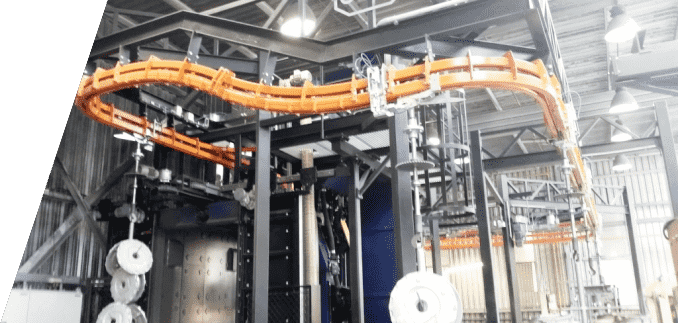

- screw conveyor and bucket elevator to transport the abrasive (in the version with elevator)

- abrasive cleaner (in the version with elevator)

- pressure blasting set (vessel volume: 40 to 200 liters) with a boron carbide nozzle of diameter 4 to 8 mm

- lighting

In order for the blasting cabin to work reliably, it must be connected to efficient suction. For this purpose, OTECO supplies an automatic environment-friendly JET filter with a fan and the air duct system alongside the cabin. This ensures continuous abrasive cleanness during blasting and prevents dust from escaping the chamber.

The complete wiring ensures proper operation and protection of the equipment. The pneumatic equipment ensures the distribution and control of compressed air for individual parts of the entire machine.